Creative solutions result in time and cost savings for clients

At Barr, we’re wired to solve problems and find solutions. Sometimes, this means stepping back and viewing the larger picture to unlock time and cost savings for our clients.

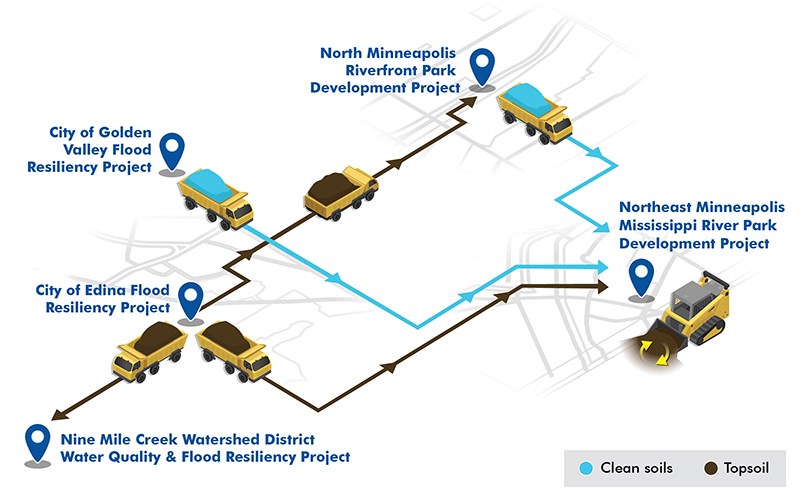

Over the past year, Barr supported five large earthwork projects within a 10-mile radius of one another in the Twin Cities metropolitan area:

-

A park development along the Mississippi River in northeast Minneapolis

-

A separate riverfront park development in north Minneapolis

-

A flood resiliency project for the City of Edina

-

A flood resiliency project for the City of Golden Valley

-

A water quality and flood resiliency project for the Nine Mile Creek Watershed District

Each project involved either the removal or addition of large quantities of soil, and each ended up contributing to the successful completion of another.

While moving soil from one site to another isn’t unheard of, these efforts are typically led by a contractor. However, in this case, Barr’s project teams recognized the opportunity to deliver a win-win solution for our clients. Given the proximity of all five project sites, Barr fast-tracked one project’s grading design so clients could take advantage of moving soil from one site to another while construction schedules overlapped. Barr’s environmental oversight and support confirmed clients were exporting and receiving clean, quality soil. This approach resulted in cost savings by transporting soil between sites instead of hauling it from elsewhere, and it reduced transportation time and minimized landfill disposal volumes. The local soil exchange also avoided potential delays resulting from truck supply chain issues.

We also helped our clients obtain two grants—$2.6 million from the Mississippi Watershed Management Organization for shoreline restoration and $700,000 from Hennepin County to manage and dispose of the contaminated soil—that will largely pay for the shoreline grading of the riverfront park development project in north Minneapolis.

“To date, between the five earth-moving projects, tens of thousands of cubic yards of soil have been excavated, with approximately 18,000 cubic yards of soil reused between the sites,” said Nathan Campeau, vice president, senior water resources engineer at Barr. “Overall, Barr helped our clients save hundreds of thousands of dollars in costs by coordinating the five projects together.”

Contact us to learn more about Barr’s environmental and civil engineering services.

About the authors

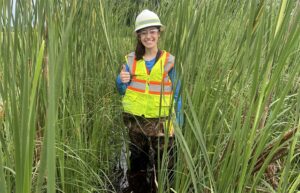

Jennifer Brekken, senior environmental engineer, has over 15 years of experience in the investigation and remediation of contaminated sites. Her project work includes developing treatability study plans and work plans for soil, sediment, and groundwater remediation; conducting human health risk evaluations; and managing investigation and remediation of former industrial and brownfields sites.

Nathan Campeau, vice president, senior water resources engineer, has over two decades of experience in hydrologic and hydraulic analysis, flood risk management, green infrastructure, and GIS. A certified floodplain manager, he works closely with watershed districts and cities on projects involving stormwater management, flood analysis and mitigation, and low-impact site design.

Michelle Kimble, senior civil engineer, has more than 25 years of civil engineering experience, specializing in site development and creative stormwater management for public and private clients. She has designed green-infrastructure retrofits that manage runoff using permeable surfaces and living systems, including rainwater gardens, rainwater cisterns for irrigation, and tree-trench filter systems.