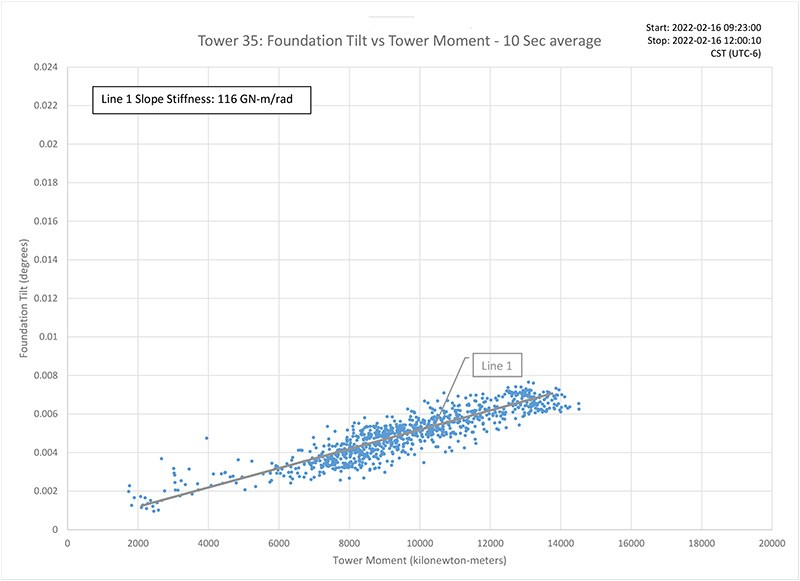

Strain gauges and tilt meters are used to conduct structural health monitoring that determines how a turbine foundation is performing.

Strain gauges and tilt meters are used to conduct structural health monitoring that determines how a turbine foundation is performing.

Foundation assessment a critical first step for wind repowering

To take advantage of better technology and current tax credits, wind farm owners are repowering their sites, often before the end of the turbines’ expected service lives. Through repowering, owners can boost power capabilities, sometimes by running fewer machines, as well as add to the grid without investing in an entirely new farm or experiencing issues related to permitting or electrical interconnections. Barr recently helped one of the largest clean energy developers in the United States repower its 150-megawatt wind farm.

The client wanted to replace existing turbines with new models and hired Barr to perform a structural assessment. Such an assessment is key in repowering because manufacturers have particular specifications for the foundations that support their turbines, and if these aren’t met, a turbine can be unsound.

Barr first conducted a desktop evaluation to determine if the proposed foundations could support the new loads. In this instance, industry design practices for anchoring the turbine towers to their foundations had changed since their original design. We developed a calculation procedure based on an analogous design formula and our knowledge of historical foundation performance. Our initial determination was that the new specifications could be met.

To validate this finding, Barr selected a subset of foundations at the site for further inspection and testing. Field investigation involved structural health monitoring (SHM) to determine each foundation’s performance while its turbine was operating. We also performed visual inspections and coring inside the foundations to check for cracking or hidden issues.

For clients, these investigation results sometimes can be a gray area; Barr specializes in evaluating risk and helping clients make informed decisions about moving forward. At this site, we determined the foundations could support the new turbines without costly modifications. Our team also developed a foundation risk-management program that consisted of performing SHM on select foundations over specific intervals. This recommendation allowed the client to move ahead with repowering while continuing to produce power for 40,000 households.

Looking for a smart solution related to repowering at your site? Contact us.

About the authors

Brian Tri, vice president, senior civil/structural engineer, specializes in steel and concrete design for foundations, buildings, and other structures. He has served as design engineer, project manager, engineer of record, and principal engineer for wind-turbine foundations on more than 100 new and repowered wind projects across the country. Brian is a member of the Barr team that provides pre-repowering assessments as well as structure and post-construction inspections for wind power projects. He also helps oversee damage evaluations for wind turbine towers and foundations, which involves site investigation, nondestructive testing, and structural analysis.

Wes Karras, structural engineer, is Barr’s wind-turbine-foundation field program manager and a member of the team that provides pre-repowering assessments as well as structure and post-construction inspections for wind projects. He coordinates foundation inspection and structural health monitoring activities related to wind-turbine-foundation assessments, including repowering. Wes has six years of experience in the wind industry and has served as the design engineer, structural inspector, and project manager on numerous wind power projects across the country.