Tailings remain one of the oil sands industry’s most complex and pressing challenges. Despite decades of progress in mining technology, these byproducts of bitumen extraction continue to pose risks to water quality, land stability, and long-term closure efforts. Addressing them requires more than technical fixes—it demands early reclamation planning, regulatory alignment, and the integration of geotechnical, geochemical, hydrological, hydrotechnical, hydrogeological, chemical, and data-driven expertise.

When done right, tailings management becomes an opportunity for innovation, collaboration, and environmental restoration—not just in the oil sands, but across the mining sector.

Technologies shaping the future of tailings management

Over the years, the oil sands industry has developed a range of technologies to reduce the volume of tailings and improve their stability:

-

Thickened tailings (TT): Uses cyclones and thickeners to recycle water before discharge, creating a denser slurry that settles more quickly

-

Composite or non-segregating tailings (CT/NST): Mixes fine tailings with coarse sand and additives like gypsum or CO₂ to produce deposits that strengthen over time and can be capped more effectively

-

Centrifugation: Uses high-speed rotating equipment to separate solids and water

-

Filtration with dry stacking: Creates stackable “cakes” that form a trafficable surface that can be used to mechanically construct a more typical mine waste structure or “tailings stack”

-

In-line dewatering: Adds flocculants (and often coagulants) just before deposition to speed dewatering of the deposited tailings; these treated tailings can also be co-deposited with coarser tailings to produce a stronger “mixed deposit” more amenable to reclamation

-

Thin lift drying: Spreads treated tailings in layers to accelerate drying through evaporation and natural freeze-thaw cycles

-

End pit lakes: Stores fluid tailings under a water cap intended to support aquatic ecosystems, though their long-term viability remains uncertain

Among the more innovative approaches supporting reclamation of these tailings deposits is deltaic capping, which mimics the natural formation of river deltas. Sand or other granular material is deposited onto a tailings surface and spreads gradually, creating a stable, layered cap over fluid fine tailings. Unlike traditional capping, which requires engineered placement and heavy equipment, deltaic capping relies on hydrodynamic processes to build gently sloping landforms.

One size doesn’t fit all

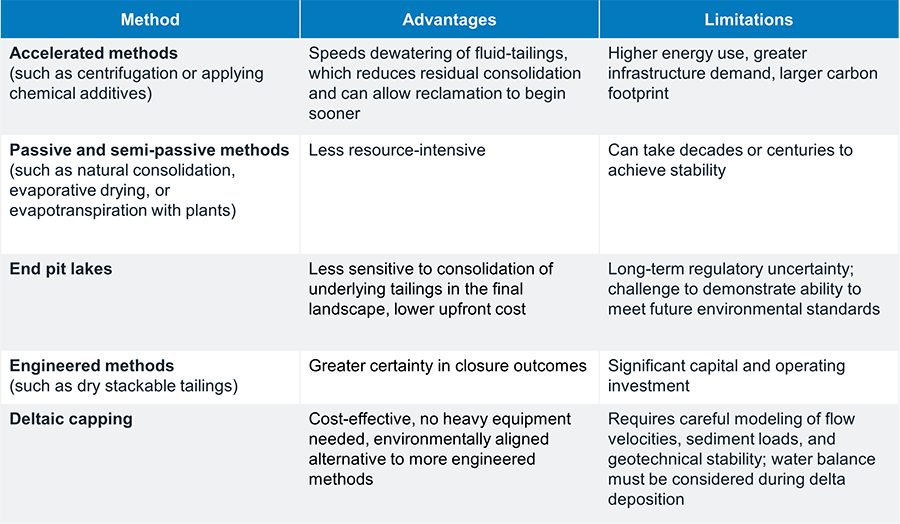

Tailings management is all about balancing trade-offs, as shown in the comparison table below. There is no universal fix, which is why Barr works across the full spectrum of technologies and expertise to help clients find the right fit for their site. From centrifugation to deltaic capping, our team of experts assess each option through the lens of long-term goals, site conditions, and environmental impact.

Comparison of tailings management methods

Adding further complexity, the chemistry and mineralogy of tailings vary across sites: swelling clays resist settling, residual bitumen impedes water release, and salts can affect tailings’ geotechnical characteristics and water quality. These differences mean a one-size-fits-all approach is not possible; tailored strategies are essential to balance short-term gains with long-term environmental and operational stability.

The power of integration

Tailings are not just a geotechnical or hydrological challenge—they’re an interconnected system that requires cross-disciplinary collaboration:

-

Geotechnical engineering helps ensure the physical stability of storage facilities but relies on chemistry to understand the effects of mineral transformations on long-term consolidation.

-

Hydrology and hydrogeology inform water balances and seepage pathways but require an understanding of settlement behavior and site geological settings to make reliable predictions.

-

Chemistry and geochemistry provide the foundation for flocculation, water treatment, and contaminant management.

-

Data science enables advanced monitoring and predictive modeling, but only when supported by high-quality inputs from other fields.

Barr brings these disciplines together, creating holistic strategies tailored to each site’s unique conditions. This approach goes beyond compliance and supports long-term ecological sustainability and operational resilience. Additionally, our unique capabilities in analyzing and designing mineral processing methods (and selecting appropriate equipment) provide an added benefit by addressing tailings in both the plant and the deposit.

Advancing tailings management through research and partnership

At Barr, we believe that sustainable tailings management is built on collaboration and continuous learning. We work alongside local and international research institutions, such as the University of Alberta and Northern Alberta Institute of Technology in Canada; participate in forums such as COSIA and the Tailings and Mine Waste Conference; and test emerging technologies through pilot-scale projects. Local expertise and global engagement help us provide solutions that not only meet today’s regulatory expectations but also push the field toward more adaptive, future-ready practices. Barr’s work in the oil sands industry reflects a commitment to innovation, collaboration, and sustainable engineering.

Looking ahead

Ultimately, tailings management is about more than just compliance—it’s about creating landscapes that can sustain future generations and traditional land uses. By rethinking tailings not as waste but as an opportunity for ecological renewal and water reuse, the mining industry can transform one of its greatest challenges into a legacy of resilience.

Connect with us next month at the Tailings and Mine Waste Conference in Banff, Alberta, or contact us to explore tailored tailings solutions for your site.

About the authors

Nav Dhadli, vice president and senior chemical engineer, has over 25 years of experience in process engineering, technology development, and project management. He has broad experience in leading the practical application of technology from concept through commercialization and has managed major front-end and detailed engineering for major capital projects within both mineable and in-situ oil sands. At Barr, he assists clients with oil sands tailings and mine water management and technology development. Nav’s experience includes leading the development and execution of several technology development programs, such as thickening of froth treatment tailings, enhanced non-segregating tailings, inline flocculation and dewatering, thin lift drying, pressure filtration, thermal drying, centrifugation, co-deposition, and hydraulic sand and coke capping of soft tailings (including leading studies and pilots related to geotechnical deformation and failure modes).

Scott Laberge, geoenvironmental engineer, has more than six years of experience with projects involving mine-closure planning and design; tailings management; geotechnical and environmental site investigations; in-situ monitoring with geotechnical and environmental instrumentation; saturated, unsaturated, and critical-state soil mechanics; geotechnical modeling; sediment transport; mine operations; tailings planning; and containment structures. He works on projects for clients in the coal, potash, metals, and oil sands sectors across North America and internationally. Scott devotes a significant portion of his work to advancing tailings-management technology and leading closure and reclamation planning for operating and legacy mine sites. His experience includes advanced geotechnical modelling of consolidation and tailings deposition planning in the oil sands, orchestrating multidiscipline technical teams for the engineering and design of a tailings-storage-facility reclamation in Canada, and supporting and directing cover-options studies and alternatives assessments for a site in northern Canada.

Jed Greenwood, vice president and senior geotechnical engineer, has 22 years of geotechnical engineering experience and has worked extensively on the investigation and design of tailings dams for U.S. and Canadian mining clients. He has led technical teams and acted as a senior reviewer on many projects, including tailings dams. Jed has also acted as an external reviewer for tailings storage facilities in various stages of operation, from before construction to in operation to previously closed, in Canada, the U.S., Mexico, Brazil, and India. Jed has performed Potential Failure Mode Analysis exercises and has been involved in other risk-informed decision making for both tailings storage facilities and hydro dams. He is skilled in numerical modeling, including finite difference (FLAC) and finite elements (GeoStudio, PLAXIS), and has expertise with high-plasticity fissured clays and shales in terms of shear strength and strain softening.

Philip Solseng, vice president, brings more than 50 years of consulting-engineering experience in the mining industry. Throughout his career, he has served as both principal in charge and design engineer on a wide range of engineering projects, including tailings dams and disposal, foundations, excavations, mine slope stability, groundwater and seepage, waste piles, reclamation, and plant facilities. Philip has led the planning and design of tailings basins for most of the major iron-ore producers in North America, as well as for facilities in Venezuela and other mineral operations across North America, South America, Europe, and Asia. His involvement with oil sands tailings dates back to the 1970s. Since the early 2000s, he has worked extensively with Deltares to develop innovative long-term reclamation disposal practices, such as Deltaic Capping.

Related projects

Geotechnical deformation and failure modeling of fine tailings capping

This project investigated hydraulic sand-cap placement as a more technically feasible and cost-effective capping method for treated fine tailings in the oil sands industry. Traditional approaches require tailings to reach trafficable strength, which can take years. As part of a collaborative project funded by the Institute for Oil Sands Innovation and Canada’s Oil Sands Innovation Alliance, Barr and Deltares used geomechanical numerical modeling (via FLAC 2D) and physical modeling to evaluate subaerial and subaqueous placement of sand and coke caps. The work is an important step in establishing a foundation for an engineering and design approach for sand cap placement.

Monitoring of end-pit lake at oil sands mine

A Canadian oil sands mine is demonstrating that water-capped tailings technology can be used to transform a former tailings basin into a lake similar in appearance and function as other regional lakes. Since 2014, Barr has monitored the lake’s fluid fine tailings through sonar surveys, sampling, and in-situ geotechnical testing to track changes in water and tailings volumes, water-cap depth, rate of settlement, and changes over time. In 2015, Barr also launched a shoreline erosion monitoring program and has since performed annual assessments and program refinements.

Testing and optimization of fine-tailings drying technologies

Since 2010, Barr has provided technology assessment and commercial deployment assistance for the “atmospheric fines drying” (AFD) oil sands tailings management program implemented by Shell Canada (now Canadian Natural Upgrading Limited). The technology is based on in-pipeline flocculant addition and tailings deposition in lifts to capture and dewater fines, guided by years of lab and field testing. Barr contributed to optimizing tailings lift thickness by evaluating drying versus self-weight consolidation through surveying, sampling, and geotechnical monitoring. The findings helped shape current commercial AFD operations, demonstrating that deep stacking offers short-term benefits, while multiple-lift strategies are advantageous with sufficient consolidation time.

Non-segregating tailings deposition study

Canadian Natural partnered with Barr and Deltares to evaluate non-segregating tailings (NST) as a strategy for meeting Alberta’s oil sands tailings reclamation requirements. Barr and Deltares developed a bench- and pilot-scale test program in close coordination with Canadian Natural to evaluate the degree to which NST slurries segregate into their component parts during deposition using different mixtures and deposition methods, with the goal of identifying which combination of slurry composition and deposition method produces the least segregated deposit. The study was completed in two parts: evaluation of sub-aqueous and sub-aerial NST deposition, and evaluation of three subaerial NST deposition methods and evaluation of deposits flowing over a long beach. Data from the tests were analyzed to develop a predictive model for NST slurry segregation behavior.