Designing new tools and solutions for stormwater quality improvement

Barr helped redesign the parking areas and pedestrian plazas of an existing retail property to reduce runoff volume and improve stormwater quality, while enhancing the user experience.

Barr helped redesign the parking areas and pedestrian plazas of an existing retail property to reduce runoff volume and improve stormwater quality, while enhancing the user experience.

Barr is industry-recognized for our innovation in stormwater management. We seek out and develop new tools and solutions that meet our criteria for good practice: performance, parameters, affordability, a small footprint for urban environments, and use of green technologies (where possible). We believe in innovation, but we also believe that innovation needs to be ground-proofed with good performance, maintainable, and cost effective for our clients.

Filtration best management practice (BMPs)

Areas of focus include infiltration and filtration practices, use of active filtration to remove particulate and dissolved constituents (metals, nutrients, and potentially others) in stormwater. Some of the filtration innovations that we have developed include iron-enhanced sand filters (first of its kind, built with recycled scrap iron) and spent-lime treatment filter (another first in the field). Recent studies include evaluating the potential for spent lime to reduce sediment phosphorus release from stormwater ponds and lakes. We’re continuing to explore the use of other innovative filtration media to remove pollutants from stormwater, such as biochar, woodchip bioreactors, CC17, and steel slag.

Pollutant and runoff modeling and management tools

In addition to BMP treatment of stormwater, Barr is also a recognized leader in the development and use of tools and models that account for runoff volume and pollutant loadings. Barr’s extensive experience with state agencies, watershed districts, cities, and BMP design allows us to develop standards and credit systems that meet desired outcomes. We developed the modeling approach and BMP design basis used to set development design standards for the State of Minnesota’s Minimal Impact Design Standards (MIDS) program, as well as nondegradation standards and rules for numerous watershed management organizations. Our team also develops water quality tools and models and conducts outreach and training workshops/conferences, including the MIDS calculator for the MPCA, the University of Minnesota’s Stormwater U series, the Freshwater Society’s Clean Water Summit, Nonpoint Education for Municipal Officials (NEMO), and the Road Salt Symposium, as well as climate change resiliency planning, construction activities training, and the development of the framework for a new chloride source assessment model and generation of BMPs on behalf of MPCA that will allow communities to evaluate their chloride source loadings and develop a chloride minimization plan.

To learn more about how Barr can help you navigate the complex challenges associated with stormwater management projects, contact us.

Related projects

Stormwater-basin retrofits improve water quality and habitat

Developers took a minimal approach to treating stormwater when designing the Ohmes Farm development. The City of St. Peters, however, wanted to improve the quality of stormwater runoff leaving the site and transform these “holes in the ground” to a natural space that residents could enjoy. Barr helped improve water quality by increasing the storage volume where possible and by incorporating iron-enhanced sand filter trenches along the path of water flow between the basins’ inlets and outlets.

Cost analysis for meeting water quality standards

Barr analyzed the capital-improvement and operational costs of enforcing existing and anticipated wastewater discharge rules from the Minnesota Pollution Control Agency. The objective was to estimate (1) the costs for average residential and commercial connections to upgrade their infrastructure to meet existing and future water-quality standards, and (2) the incremental changes the upgrades would create in the quality of receiving waters.

First-of-its-kind spent-lime stormwater BMP treatment system

Barr developed a first-of-it-kind spent-lime treatment cell for the Ramsey-Washington Metro Watershed District to reduce phosphorus loading to Wakefield Lake, an impaired lake located in Maplewood.

Removing dissolved metals from roadway runoff using ferric-oxide filtration

Barr designed and conducted a study for the National Cooperative Highway Research Program to field test the effectiveness of ferric-oxide media in sand filters for removing dissolved metals—such as copper, lead, zinc, nickel, and arsenic—from highway runoff.

Image gallery (below):

-

Barr designed and implemented a first-of-its-kind spent-lime stormwater BMP treatment system to help improve water quality in an impaired lake.

-

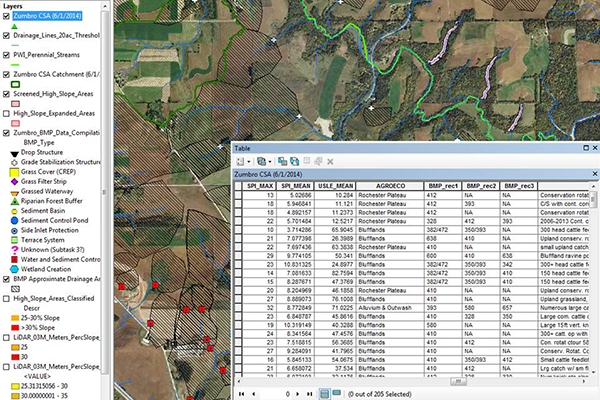

Barr's work on the Zumbro River Watershed Restoration Prioritization project included a GIS database complete with a prioritized list of upland and near-channel critical source areas and associated BMP recommendations for each site.